Riyas P.K-Fab Academy 2016

Mechanical Design

This week we have a group assignment.The assignment is to make a machine, including the end effector, build the passive parts and operate it manually, document the group project and your individual contribution.

Our Team

After group discussion, we decided to build mini version of an electric wheelchair which could be used by handicapped children, specifically for children with no legs.After we made structure due to the lack of affordable motors to drive a wheelchair we decided to change it to an automatic cleaning machine.Also we decided to make the machine from scrap and hence named it as "Scrap Bot".The project tasks were divided and given to each members.For documentation of the project, we created a seperate group page as per the requirement.

My Contribution

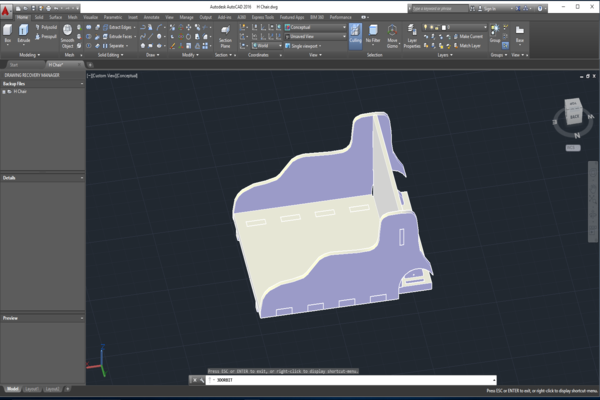

I along with Athif did the mechanical part of the project.Since our original idea was to create a mini wheelchair,after making some rough sketches we designed the platform in autocad.

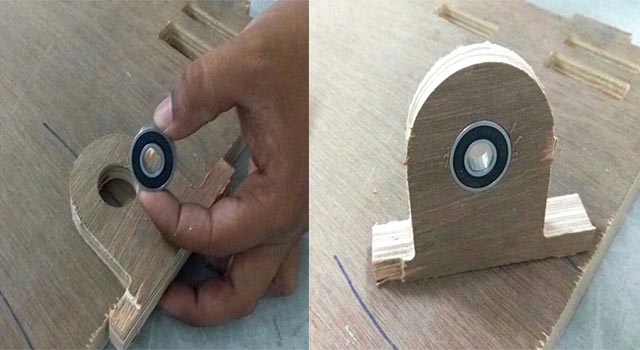

It was then machined using shopbot.As you can see the design was a press fit ,it was quite simple to assemble the machine parts.We had a thought to properly utilize fab inventory items we have in our lab.So Athif had this idea to make wheels using plywood and rubber sheet, we used it as rear wheels of the machine.For front wheel we had to buy freely movable wheels.

The axle is also made up of plywood and is stationary.At the center of axle there is hole to place the ball bearing which helps to fix the shaft at a time,and also allow it to rotate.

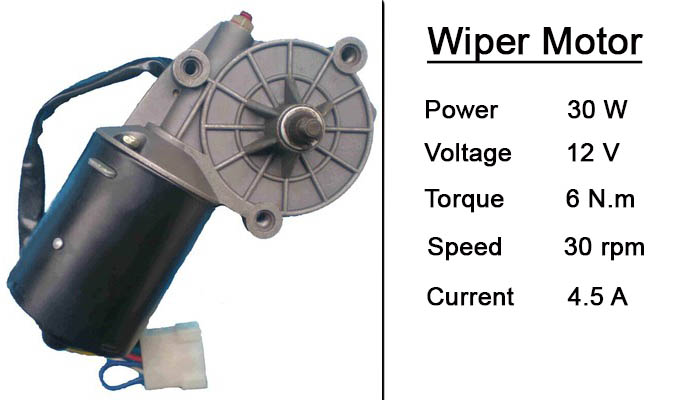

The motor we used to drive the machine is a wiper motor which we bought from a scrap shop.We used two of it, each for two rear wheels.

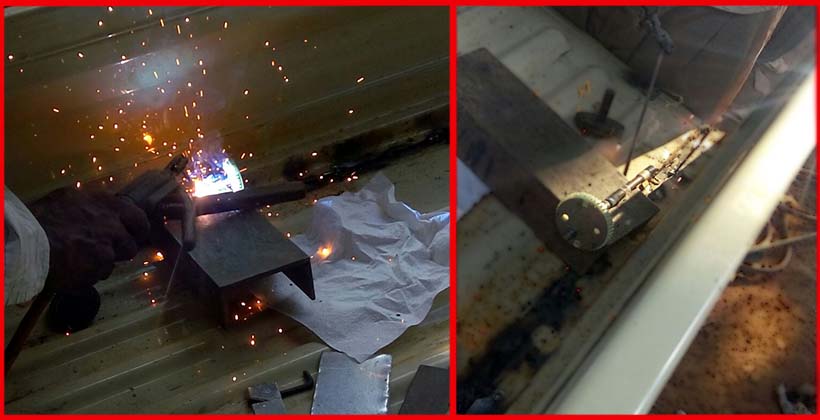

Since the shaft of the motor was small, we increased it's length by welding a similar sized rod to it at a local workshop.

After assembling the body, motors and wheels our part of the project (mechanical) was ready.